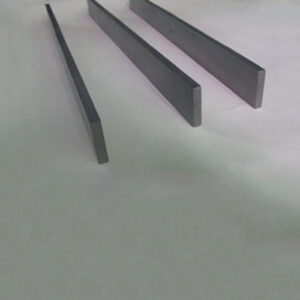

Highly wear resistant tungsten carbide composite rod is made of sintered tungsten carbide grit and flexible base metal. It is coated with a special flux and colored to identify the particle size. The sintered cemented carbide particles are mainly cobalt-containing tungsten carbide, the hardness is HRA89-91, the matrix metal is "nickel-copper" alloy,which is naturally crushed. The particles with the same size are selected and mixed with the matrix alloy containing elastic copper, nickel and zinc .tire body metal is Ni and Copper alloy, strength can up to 690Mpa.hardness HB≥160.outer layer of special flux and color of the electrode used to identify the grading size of cemented carbide particles.As its high abrasive and strength、excellent weldability, therefore, it is an excellent hard facing material. Such as the tungsten carbide composite rod is also called tungsten carbide brazing rod , YD cemented carbide composite surfacing electrode , tungsten carbide welding rod, has been respected throughout oil drilling, mining and construction industry worldwide, even spreading more and more industries and get greater using. The cemented carbide composite rod has high wear and cutting properties, weldability and low fuming , it is successfully used like stabilizers, reamers, construction drilling, drill pipe joints, pipe cutter blades, hydraulic cutter , scraper , core bit , piling drill, twist drill , milling and grinding shoes , etc.

The YD type electrode needs to be used in conjunction with a base electrode (YD-D) and a special flux (YD-R).

The YD-D base electrode is a gas welding electrode with a special flux coated on the outer skin. The amount should be the weight of 15% of the YD electrode.

YD-R is a compound flux, and the amount should be 2% of the weight of the YD electrode.

All has been providing as whole matching portfolia from Weison Advanced Materials.

* surfacing on the workpiece for manufacturing new tools

* surfacing on workpiece for restoring broken parts.

Advantages of Tungsten Carbide Composite Rod

•Prolongs the life of parts and increases efficiency

•Diminishes equipment downtime as it keeps equipment longer working.

•Productivity and profitability is increased

•Reduction of spare parts inventory.

•Resurfaced parts will aid to decrease stocks of new parts normally necessary for emergency and general replacement

•Less expensive base metal can be used

•Overall cost are reduced

•More abrasion resistant than Chromium Carbide

•Provides 300%-800% wear life compared to typical hardfacing rods

•Easy to apply

* Tungsten carbide composite rod specification

|

grade |

size (mm) |

scrap size (mm) |

color |

|

YD-9.5 |

9.5 |

9.5~6.5 |

dark green |

|

YD-8 |

8.0 |

8.0~6.5 |

dark blue |

|

YD-6.5 |

6.5 |

6.5~5.0 |

red |

|

YD-5 |

5.0 |

5.0~3.0 |

yellow |

|

YD-3 |

3.0 |

3.0~2.0 |

pink |

|

YD-10 |

10 mesh |

10~18 mesh |

light green |

|

YD-18 |

18 mesh |

18~30 mesh |

light green |

|

YD-30 |

30 mesh |

30~50 mesh |

light yellow |

1 large particles are suitable for surfacing of oil pipeline cleaning equipment

2 small particle are suitable for surfacing of large mixer blades

3 smaller particles are suitable for root tree grinding machine

Composite rod sizes

70% YD3 L280mm

70% YD5 L280mm

70% YD3 L450mm

70% YD5 L450mm

70% YD6.5 L450mm

70% YD8 L450mm

70% YD9.5 L450mm

Custom Made

Tungsten carbide Hardfacing consumables

●tungsten carbide electrodes

●tungsten carbide oxy/tig rods

●tungsten carbide mig

●tungsten carbide sintered parts

●tungsten carbide/chrome carbide powders

Working condition of Tungsten carbide composite rod

(1) clean the workpiece to expose metallic luster on the surface of the welder.

(2) take the position of flat welding for surfacing. For this purpose, appropriate placemas can be used to control the thickness of the surfacing layer and the thickness limit block can be used.

(3) preheat with neutral flame. Do not touch the surface of the workpiece with the flame core. The distance should be 25mm.

(4) surfacing hard alloy welding layer.Use YD welding electrode for surfacing and use neutral flame (slightly carbonized flame) to move evenly and smoothly on the workpiece surface Heat the alloy electrode (do not make the flame tip contact the alloy particles) to melt the matrix alloy in the electrode, and then the cemented carbide particles fall together. Before the molten matrix metal solidifies, the particles are arranged and may be pulled up using an alloy electrode held in the left hand, or another person holding a bottom-electrode or stone The ink stick as a bar, in a quick manipulation of the particles, so that the arrangement of uniform.The thickness of the surfacing layer is controlled according to the design requirements.

(5)after the workpiece is welded, it shall be placed in an unventilated place, and it shall be cooled slowly and not be chilled rapidly. If available, it can be covered with asbestos blanket.

(6)after the workpiece is cooled to room temperature, the surfacing can be ground to the required size and shape if necessary.

(7)clean up the workpiece and remove all spatter, slag, etc.