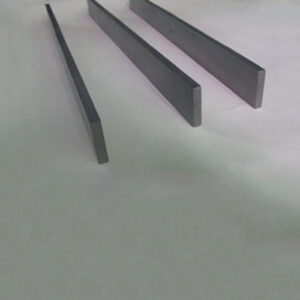

Multi-application product: Tungsten carbide grits

Tungsten carbide grits/granules are widely used in various industrial applications where a high level of abrasion and corrosion if predicted within the work environments like in the oil industry. The granule size can be altered to achieve the desired levels of impact. The method of hardfacing involves the applying of a tougher and harder metal like tungsten carbide to a base metal. This creates stronger tungsten carbide granules for usage in oil industries and other sectors where high protection against wear and abrasion is required.

High purity Tungsten carbide grit , also called cemented carbide granule or WC grit , is an excellent hard-facing wear resistant materials, widely used on the surface of those who produce severe wear , friendly protect workpiece, increase its efficiency and extend lifespam. The tungsten carbide pellets will produce an extremely aggressive cutting or grinding surface, increase the wear life of hardfacing deposits.

The making process

The traditional process of making tungsten carbide granules involves the crushing of larger compositions of tungsten carbide. The same however resulted in sharp faceted, irregular shaped particles without the much-needed wear resistance. The irregular shapes often succumbed to high pressure and wear conditions which made them a poor choice for oil industries.

The modern process, however, relies on preparing tungsten carbide powder with which different shapes like spheres, cylinders, ovoids, etc are created using a suitable organic binder for use in tough work environments. These so formed tungsten carbide granules provide high strength and wear resistance making it suitable for working in the oil industry.

The use

Crushed Tungsten carbide grits have a wide application ranging from use in grinders, agricultural industry, use in wear parts and plow attachments, etc. The usage of tungsten carbide grits in the oil industry in applications like hardbanding, drill pipes, drill collars, pup joints, etc is well noted.