Tungsten Carbide Hardfacing

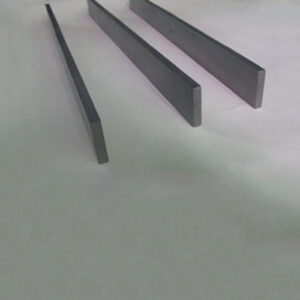

Hardfacing is a process of making the base metal tougher and harder by applying another stronger material on its surface. Materials like tungsten carbide grit work excellent in industrial processes that undergo extreme conditions like the oil industry and so forth. Tungsten carbide hardfacing is hence highly popular technique offering high levels of wear and abrasion resistance at the required locations.The purpose is to restore the outer surface hardness of the workpiece or increase the outer size of the workpiece.After the workpiece material surfacing layer is worn, surfacing again can improve the service life of the whole part, save the manufacturing cost and maintenance cost, shorten the repair and replacement time of the whole part, reduce The Times of production stoppage and the loss of production stoppage, and reduce the production cost as a whole.Surfacing can make better use of materials to obtain excellent comprehensive performance, and it is also of great significance to improve product design.

The use

When tungsten carbide grit was first considered for hardfacing, the crushed granules which were irregular in shape did not offer the much-needed wear-resistance. Owing to their irregular shapes, the granules easily succumbed to extreme conditions of temperature and pressure as prevalent in various industrial processes. The same gave birth to the invention of the modern process of creating perfectly shaped (spherical, ovoids, cuboids, etc) tungsten carbide grit using tungsten carbide powder along with an organic binder. The grit so formed comes with high strength and wear resistance making it a perfect hardfacing material for the oil industry.

Tungsten carbide hardfacing in the oil industry is an important process used in applications like hardbanding, drill pipes, drill collars, etc. Tungsten carbide grit offers high levels of protection to the surfaces of these parts which is a necessity considering the extreme conditions prevalent in the oil industries. In addition to its applications to new parts, tungsten carbide hardfacing process is often used to restore some deteriorated and worn down surfaces of old parts of various machines and equipment in the industries

What’s more , tungsten carbide spherical is most cost efficient hardfacing materials, the tungsten carbide ball grain has superior impact and wear resistance. mixture of WC and spherules in proper proportion with different composition and particle size have very high resistance to abrasion and impact. Nonrecurring welding without repetition and high hardness. Famous wear and corrosion resistance, high cobalt alloy spheres with small spherical friction coefficient can be used to solve the casing wear problem in a more cost effective way. Tungsten carbide pellet widely used in surfacing, deposited weld in a variety of tools and parts surface to form hardened layer grinding , with its excellent characteristic can improve the tools and parts’ surface hardness , wear resistance , corrosion resistance significantly , and extend longer lifespan. In long running , it brings good economic effectiveness used in oil industry and will widely spread to greater benefit

WEISON are the market leaders in manufacturing tungsten carbide hardfacing field on surface of base piece or inner wall of base piece,help customer provide multitude hardfacing solutions to maximize workpiece life under easily working environment control. welcome customized tungsten carbide hard facing or sets surfacing, WEISON will be your best solution partner in high abrasive tungsten carbide hardfacing